Custom Private Bowling Alley Design Standards | Pre-Construction Guide

Explore Flying Bowling's Pre-Construction Guide to Custom Private Bowling Alley Design Standards. Learn layout, materials, safety, and acoustic best practices to build a High Quality residential or commercial alley. Download our checklist and start planning today.

- Introduction

- Bowling Equipment Selection

- Room Length

- Room Width

- Ceiling Height

- Machinery Room

- Maintenance Storage

- Soundproofing

- Loading

- Pit Dimensions

- Flatness

- Verticality

- Conduit Installation

- Finishing Materials

- Accessory Storage

- Ceiling Design

- Lighting Design

- Wall Design

- Safety Barriers or Half-Walls

- Electrical Design

- Pinsetter

- Electrical installation:

- Ball return machine

- Foul Detector Power Supply

- Score Display and Computer

- Curtain Wall Sockets

- Special Effects Lighting (Optional)

- Automatic Guard Rails (Optional)

- Electrical Summary

- Site Preparation

Introduction

Designing and building a custom private bowling alley is a complex project where careful planning and strict adherence to technical standards are essential. This pre-construction guide, based on Flying Bowling's expertise, outlines the critical requirements that homeowners, architects, and contractors must consider before installation begins. Every detail is important for a smooth construction and long-term performance, from room dimensions, ceiling height, and pit foundation specifications to electrical supply, scoring systems, lighting, and soundproofing.

If you follow these guidelines and work closely with your equipment supplier from the start, you can avoid costly design errors, installation delays, and create a bowling environment that combines safety, functionality, and entertainment value. This intro sets the stage for a comprehensive checklist that'll support your project from planning to completion.

Bowling Equipment Selection

First, ensure these large bottle-setting machines can be moved smoothly into the building. The largest component of the machine measures approximately 5.5 feet (1.7 meters) wide, 7 feet (2.1 meters) long, and weighs about 1,200 pounds (520 kilograms). Plan in advance the route the machine will take from the truck on the street into the building, then through the building to the bowling alley. This requires double doors (6 feet wide) and wide corridors. The lane lining panels measure 18 feet (approximately 5.5 meters) in length, so avoid sharp turns in corridor designs. If the bowling alley is located in a basement, ensure at least one side features a walk-in basement with a ground-level entrance.

Room Length

For a standard-sized bowling alley, the room length should be approximately 100 feet (about 30 meters). The bowling equipment itself requires 87 feet (approximately 27 meters) of space—including the auxiliary lane (16 feet), the lanes and ball return (67.5 feet), and the service lane behind the ball return (at least 3.5 feet). Add a seating area (roughly 13 feet is sufficient), and you have a 100-foot (approximately 30-meter) space. See illustration on page 3.

Of course, you could position the seating area alongside the auxiliary lane to reduce overall length. However,

spectators will find it more enjoyable to watch the ball's trajectory directly along the lane. Another space-saving approach is to have us cut/splice lane material to create a shorter, non-standard bowling lane. This can save up to 6 feet (approx. 1.8 meters) from the auxiliary lane. Theoretically, you could reduce the lane length to almost zero—it's simply a matter of “how short is too short?” which only the client can judge.

Room Width

The table below lists the minimum room widths required for a bowling alley. Theoretically, the room's side walls could be flush with the bowling equipment's sides, but we strongly advise against this. Doing so would make the room feel more like a tunnel, not to mention bowlers risking knuckle scrapes during throws! That's not ideal. In practice, if adjacent spaces have compatible uses (e.g., recreational activities), we recommend removing one or both side walls.

| Lanes | Width of Equipment | Suggested Side Aisle Width |

| 1 | 8 feet (ideal); 6 feet 9 inches (minimum) | 3 feet on each side |

| 2 | 11 feet 6 inches | 3 feet on each side |

| 3 | 17 feet 4 inches | 3 feet on each side |

| 4 | 22 feet 8 inches | 3 feet on each side |

Ceiling Height

The optimal ceiling height is approximately 10 or 11 feet (around 3.0 to 3.4 metres). As bowling alley spaces are very elongated, having sufficient height will help the room feel balanced and reduce any sense of claustrophobia. The absolute minimum height is 8 feet (approximately 2.4 metres).

The limiting factor is the height of the pin setting machine area. Ensure sufficient clearance for technicians to access the top of the ball setting machine.

Machinery Room

The mechanical area housing the ball setting machine must be enclosed and accessed via a lockable door.

The wall in front of the ball setting machine is a curtain wall with openings through which the bowling lanes and gutters pass. The rear of the curtain wall should be positioned 71 feet (approximately 22 metres) from the front edge of the lanes.

Maintenance Storage

Remember to designate an area for storing maintenance tools and supplies for the bowling equipment. A separate storage room is preferable. If unavailable, the service passage (if sufficiently wide) may double as storage space. Additional space is required if opting for an automatic cleaning/oiling machine.

Soundproofing

Avoid locating the bowling alley adjacent to nurseries or meditation rooms! However, if unavoidable, mitigate vibration/sound transmission between rooms by designing an offset wall structure. Fill the wall cavity with insulation material and install double-layered plasterboard on one side.

These illustrations depict one of numerous possible design options and are provided for discussion purposes only. No design or construction should be undertaken based solely on these drawings. At any stage of your project, please contact Flying Bowling for a friendly and complimentary consultation. We would be delighted to assist you in designing the perfect bowling centre!

Loading

A pair of assembled bottle-setting machines weighs approximately 5,000 pounds, with most of the weight concentrated on the narrow bases at each side of the machines. The optimal foundation for a bowling alley is a reinforced concrete slab at least 4 inches thick, sealed to minimise dust.

Pit Dimensions

Create a recessed area within the concrete slab, termed the ‘pit’. The pit's length should be at least 87 feet (approximately 27 metres), with a depth precisely 17 inches (approximately 43 centimetres). We can slightly adjust the height using shims based on the thickness of the finished floor material adjacent to the bowling alley, ensuring the floor sits flush with the ground.

The width of the concrete slab pit will vary depending on the number of lanes. Please refer to the equipment width table above. These widths already incorporate a small margin for concrete imperfections, so no additional width needs to be added to the figures in the table.

Flatness

Ensure the concrete flatness across the entire bottom area and the top edge of the pit is within 1/2 inch. The height of the bowling lane will be determined by the highest point of the top edge of the channel. As the bowling lane's flatness will be less than 0.004 inches, any imperfections in the concrete slope around the bowling lane will appear more pronounced alongside the flat lane surface.

Verticality

Ensure both sides of the pit are vertical. Constructing the pit sides using CMU blocks yields better results than pouring behind timber formwork. Formwork tends to sag inward, causing the pit shape to undulate and resulting in a narrower pit than planned.

Conduit Installation

Embed a 1-inch electrical conduit within the slab to supply power to equipment beneath the lane. This may be routed from either side of the pit. Position the conduit approximately halfway along the lane (8 feet from the pit front). Its exact location is inconsequential, as the structure beneath the lane remains open, permitting wiring access from any point below.

Finishing Materials

Soft finishes are preferable to hard finishes. The following suggestions help absorb

unwanted reverberation, making rooms feel more comfortable.

• Use carpets instead of wooden floors or tiles. (Moreover, tiles may crack if someone drops a bowling ball.)

• Install acoustic ceiling tiles and/or suspended decorative sound-absorbing panels instead of a 100% plasterboard ceiling.

• Incorporate fabric-wrapped panels on walls rather than using solely brick or plasterboard.

Accessory Storage

Near the bowling area, ensure provision for storing guests' bowling shoes and balls.

The joiner should be able to create built-in shelving, parallel rails and/or storage compartments.

Ceiling Design

We recommend adding some form of ceiling beams (typically four, spaced evenly along the lane) perpendicular to the lane, or creating a similar ‘serrated’ ceiling profile. These ceiling designs serve two purposes:

• To break up the long, flat, monotonous ceiling, lending it visual interest.

• The rear of each beam (or the vertical section of each ‘serration’) provides an ideal location for mounting any unsightly light fixtures, whilst also shielding bowlers from glare.

Lighting Design

Consider employing bright, uniform lighting above the lanes to assist bowlers in tracking their ball's trajectory. Utilise more traditional, subtly subdued lighting in the bowler seating area. Ensure the pin-setting machine's mechanical zone is well-lit (simple surface-mounted luminaires may suffice) and incorporate a circuit with an independent switch.

Wall Design

Incorporate pilasters or half-columns along walls to break up the room's elongated appearance. Avoid elements running parallel to the lanes (such as armchairs), as these accentuate the issue. Where feasible, consider

removing one side wall of the bowling alley, or at least adding glass walls, windows, or

openings to visually and acoustically integrate adjacent leisure spaces.

Safety Barriers or Half-Walls

Where foot traffic is heavy alongside the bowling lanes, consider installing safety barriers to prevent tripping over gutters and greasy lanes. Barriers need not extend the full length of the lane – they may terminate at the sideline. Alternatively, construct half-walls as a substitute for full barriers. Should this approach be chosen, consider designing the wall top with a sloping edge to deter patrons from placing drinks against it.

Electrical Design

Sub-Panel

A dedicated sub-panel with isolated grounding is required. A typical two-lane bowling alley requires a 100-amp sub-panel. Install this within the mechanical area behind the pin setting machine. Only bowling equipment listed in this guide should be connected to the bowling sub-panel. General interior lighting and wall sockets should be connected to a separate panel.

Pinsetter

Provide a power input for each pair of pinsetters. A surge suppressor (supplied by Flying Bowling) must be installed on the subpanel to protect the pinsetter's electronics. Pinsetters require three-phase power, but you have the following options:

1. The preferred option is to connect a 208V three-phase power supply directly to the pin setter. Run a rigid conduit between sub-panels, connecting to a junction box near the pin setter. Continue the connection to the pin setter via flexible conduit. If the junction box is suspended from the ceiling, use a stress relief fitting.

2. If three-phase power is unavailable, the next best option is to connect 230V single-phase power to a phase converter (supplied by Flying Bowling), then run a pair of rigid conduits (one for high voltage, one for low voltage) to a junction box near the bottle setter. Flying Bowling will provide a low-voltage control relay that automatically activates the phase converter when the bottle setter is in use.

Flexible conduit connects the wall-mounted junction box to the bottle setter.

Socket for the under-lane ball return lift.

Continue the high-voltage connection to the bottle setter via flexible conduit. Use a strain relief connector if suspended from a ceiling-mounted junction box.

Below is a summary of electrical details for the bottle setter.

• Single circuit per pair of pinsetters; 20A circuit breaker;

Approx. 12A current draw; total power 3 HP per pair of pinsetters.

• 208V three-phase power supply (or 230V single-phase with phase converter).

Electrical installation:

•Surge suppressor, mounted on wall near sub-panel.

•Rigid conduit connected to a junction box near the left side of the left-hand pin setter (as viewed from the bowler's perspective).

•Phase converter (supplied by Flying Bowling if required), installed on the floor behind the pin setter.

•Junction box located near the left side of lane 1 (as viewed from the bowler's perspective).

•Flexible conduit connecting from the junction box to the pin setter. (Should power be suspended from the ceiling, employ a strain relief connector.)

• Timing: Coordinate with Flying Bowling's installation team for fitting after the ball setting machine is in position.

Ball return machine

A ball retriever is situated centrally in the approach area, positioned between each pair of lanes. The ball retriever lifts balls that roll beneath the lanes and return forward, raising them to ground level. It incorporates a 1/2 horsepower thermally protected motor controlled by a low-voltage relay circuit (supplied by Flying Bowling). The ball return lift motor operates only when the pin setter is energised.

• 1 circuit (up to 4 lanes); 115 volts; 15 amp circuit breaker; approximately 6 amps per pair of lanes; 1/2 horsepower.

• Electrical installation: Double socket outlet

• Location: Beneath the approach area.

• Timing: Coordinate with the Flying Bowling installation team to connect power to this location during bowling installation, before the under-lane structure is covered.

• Note: Accessible via a removable hatch on the walkway after the bowling centre is completed.

Foul Detector Power Supply

An infrared foul detector monitors a single pair of lanes positioned near the foul line (16 feet from the front of the approach). We recommend installing the foul detector within a circuit equipped with a switch. During construction, a double socket must be fitted beneath the lanes. Once the bowling lanes are complete, the first layer of covering can be removed for operation.

• Single circuit (up to 4 lanes); 115 volts; 15 amp circuit breaker; approximately 1 amp per lane pair.

• Electrical installation: Double outlet socket.

• Installation location: Beneath the lane, near the foul line.

• Installation timing: Coordinate with Flying Bowling's installation team during bowling alley construction to connect power to this location before the lane-side structure is covered.

• Install wall switches in locations convenient for bowlers.

Score Display and Computer

Each lane is equipped with one score display, and each pair of lanes shares one scoring computer. The compact computer unit is mounted behind one of the displays. Displays are typically (supplied by Flying Bowling) ceiling-mounted at approximately mid-height of the approach line. The most common display size is 46 inches. The ceiling must be reinforced to safely support the combined weight of the display, computer, and mounting bracket (maximum 250 lbs). Contact Flying Bowling for further guidance regarding wall-mounted installations or detached displays.

A 1-inch (approx. 2.5 cm) conduit must be installed above the ceiling to allow connection of the data cable from the scoring computer to the pin setter. This conduit should terminate in a flush-mounted box, with cables passing through the cover plate and extending down one of the two support tubes of the display mounting bracket. A double socket outlet should be installed near the other support tube. Both support tubes should be positioned directly above the centre of each pair of lanes, spaced 50 inches (approximately 122 centimetres) apart.

• Single circuit (up to 4 lanes); 115 volts; 15-amp circuit breaker; maximum current 6 amps per pair of lanes.

• Electrical installation:

o Double socket outlet installed above the lane, flush with or above the ceiling.

o Conduit runs from the scoring display to the rear of the curtain wall. Space power outlets and conduit junction boxes 50 inches (approx. 122 cm) apart, positioned directly above the centre of each pair of lanes.

• Timing: Coordinate specific positioning with Flying Bowling and install prior to plasterboard fitting.

• Television, satellite inputs, TV controllers etc. (if applicable) to be installed by audio/video contractor.

• Main contractor shall provide adequate structural support within ceiling or walls.

Curtain Wall Sockets

The curtain wall is suspended in front of the bottle setting machine, separating the mechanical area from the public zone. The rear surface of the curtain wall serves as the mounting plane for various bowling equipment components. Two double-gang power sockets must be installed on the rear of the curtain wall (one pair per lane). These sockets supply power to lane accent lighting, temporary technician tools, retractable projection screens (where fitted), and other assorted bowling equipment.

• 2 circuits (up to 2 lanes); 115V; 20A circuit breaker; maximum current per circuit up to 18A.

• Electrical installation: 2 dedicated double-gang sockets.

• Installation location: Behind the curtain wall.

• Installation timing: Prior to fitting plasterboard.

• Flying Bowling shall install the LED lighting system (if applicable) and coordinate with the audio/video contractor to connect the DMX controller and/or projection screen controller (where required).

Special Effects Lighting (Optional)

Many newly constructed bowling alleys incorporate some form of special effects lighting, ranging from ultraviolet lamps for “glow-in-the-dark” or “cosmic” bowling parties to full DMX-controlled nightclub-style systems featuring strobes, rotating LEDs, or laser projections. Ceiling configurations and available options vary significantly between venues, meaning some or all of this section may not apply. Consult Flying Bowling before commencing construction.

Should clients be uncertain about special effects lighting, or wish to maximise flexibility for potential future upgrades, we recommend the following configuration for dual-lane bowling alleys: Install four rows of three-hole double-gang power outlets along the ceiling, starting from the sideline (left, centre, right).

This provides multiple options for arranging varying numbers and types of fixtures.

• 1 lane (up to 2 lanes); 115V; 20A circuit breaker; maximum current per pair of lanes 12A or higher.

• Electrical installation: Multiple double outlets (typically 12)

o Circuit control is usually via wall switches. (Upgrade packages may include control via

DMX technology and touch panels. Please coordinate with Flying Bowling.)

• Installation location: Entire ceiling, above bowling lanes. Specific locations and quantities to be determined.

• Installation timing: Prior to plasterboard installation.

Automatic Guard Rails (Optional)

Most bowling alleys are equipped with retractable guard rails to prevent children from retrieving balls from the gutter. Some rails are manually operated, while others are automatic—driven by motors controlled by the scoring system. Like the ball return hoist and foul detector, power for automatic guard rails is supplied via conduits embedded in concrete beneath the lanes.

• Single circuit (up to 4 lanes); 115 volts; 15 amp circuit breaker; 3 amps per pair of lanes.

• Electrical installation: Double socket outlet.

• Installation location: Beneath the bowling lanes, 44 feet (approximately 13 metres) from the front edge of the pin return lane.

• Installation timing: Coordinate with Flying Bowling's installation team to connect power at this location during bowling installation, before the under-lane structure is covered.

Projector (optional)

A commercial-grade, high-lumen HD projection system is available as an option. The projector (supplied by Flying Bowling) is suspended above the centre of two lanes, approximately 53 feet from the front of the approach lane (consult Flying Bowling for exact positioning). The projector is typically connected to 1-1/4-inch threaded conduit (installed by the main contractor).

A 1-inch conduit must be installed above the ceiling to connect the projector to the rear of the projection wall, enabling signal transmission to the retractable projection screen when the projector is powered. The conduit should connect to an embedded junction box with a cover plate. Install a double socket outlet adjacent to the projector location. Consult Flying Bowling for precise positioning.

• Single circuit (up to 4 lanes); 115 volts; 15 amp circuit breaker; 3 amps per pair of lanes.

• Electrical installation:

o Double socket outlet, positioned centrally between two lanes.

o Ceiling conduit, connecting to rear of screen wall.

o 1.5-inch threaded conduit (may require installation by other trades).

• Installation location: Within ceiling, 53 feet (approx. 15 metres) from entrance front, positioned centrally between dual lanes.

• Installation timing: Prior to plasterboard installation.

• Cable TV, satellite TV, DVD input interfaces, etc., to be installed by audio/video contractor.

Electrical Summary

| Device | Power Location | # Circuits | Voltage | Current | Breaker |

| Pinsetter | Wall or ceiling near pinsetters | 1 (up to 2 lanes) | 110-230V | 12A per 2 lanes | 15A |

| Ball Return Lift | Under center of approach | 1 (up to 4 lanes) | 110-230V | 6A per 2 lanes | 15A |

| Foul Detector | Under lanes, near foul line | 1 (up to 4 lanes) | 110-230V | 1A per 2 lanes | 15A |

| Scoring Displays & Computer | Ceiling above approach | 1 (up to 4 lanes) | 110-230V | Up to 6A per 2 lanes | 15A |

| Curtain Wall Receptacles | Back of curtain wall | 1 (up to 2 lanes) | 110-230V | Up to 9A per lane | 20A |

| Special Effects Lighting |

Throughout ceiling above lanes | 1 (up to 2 lanes) | 110-230V | Up to 12A per 2 lanes | 15A |

| Automatic Bumper Rail |

Under lanes | 1 (up to 4 lanes) | 110-230V | 3A per 2 lanes | 15A |

| Video Projector | Ceiling above lanes | 1 (up to 4 lanes) | 110-230V | 3A per 2 lanes | 15A |

Site Preparation

Prior to delivery and installation of bowling alley equipment, the following must be in place:

1. The permanent electricity meter must be operational. Temporary construction meters will not be accepted. Equipment must be installed and tested using a permanent three-phase power supply.

2. The HVAC system must be fully functional to allow lane materials to acclimatise.

3. All painting work within the bowling centre must be completed.

When you begin designing your brand new custom private bowling centre, contact Flying Bowling for a complimentary consultation by calling 0086-150 1310 7020 or emailing jackson@flyingbowling.com!

Quality Bowling

Company

What are the advantages of your brand compared with other international brands?

Compared with other international brands, our equipment has significant price advantages and lower maintenance costs. We provide customers with more cost-effective options by optimizing the design and manufacturing process while ensuring high quality and compliance with USBC international standards.

Customer care

My room isn't quite long enough. Can you install slightly shorter lanes that are non-regulation length?

Of course, we can customize bowling lanes according to your venue.

Service

If there is a problem with the equipment, how long will it take you to respond?

We promise to provide a solution within 12 hours (24 hours for overseas customers), and serious failures will be handled first.

Products

What is the noise level of the equipment?

We are well aware of the importance of a quiet and comfortable environment for bowling, so we designed sound insulation cotton and shock-absorbing pads in the equipment area and the lane area to fully reduce the noise and vibration of the equipment during operation, creating a quiet and comfortable sports space for you, allowing you to focus more on enjoying the fun of bowling.

Can I choose the color and brand logo of the equipment?

Personalized customization is supported, including lane color, LOGO, theme lighting system, etc.

You May Also Like

Flying Smart Duckpin Bowling

The innovative design of Flying Smart Duckpin Bowling (FSDB) makes it perfect for places like bars, billiard halls, and game centers. It makes people want to come back more often and spend more money. FSDB is fun and competitive, so it will become a new focus for social activities.

Flying Classic Standard Bowling

Flying Classic Standard Bowling (FCSB) employs the World Standard Competition Scoring System to deliver a more professional bowling experience, enabling bowlers to enjoy a professional-standard match at their convenience.

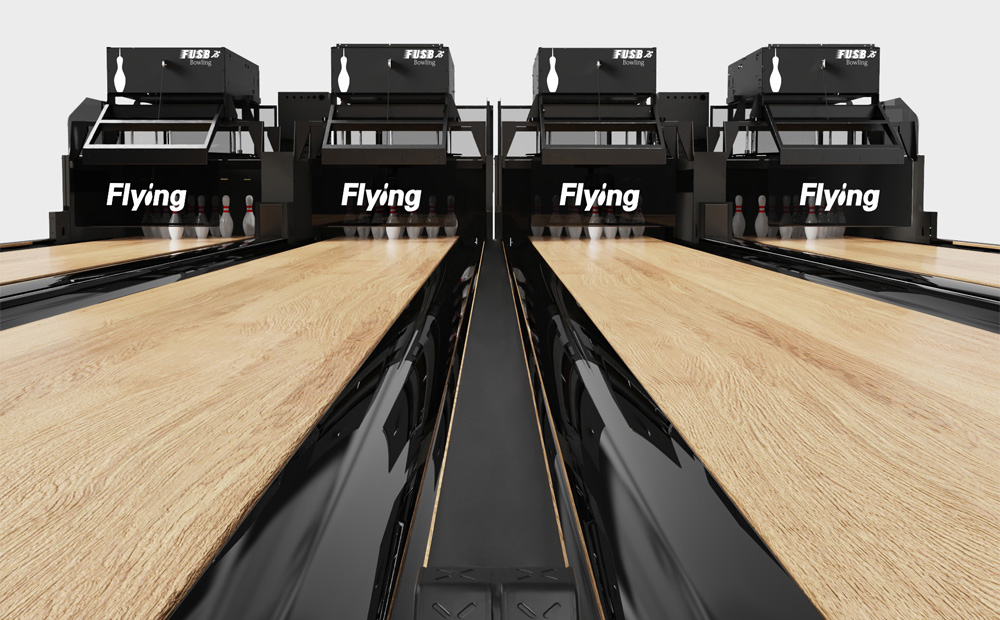

Flying Ultra Standard Bowling

Flying Ultra Standard Bowling (FUSB) Upgraded Version

The string pinsetter uses the latest technology. It offers a more enjoyable bowling experience thanks to its innovative designs and modern technology.

Get in touch

Contact us

If you contact us now for more details, we can provide you with a custom bowling alley service.

Our service team will get back to you within 24 hours, normally!

Facebook

YouTube

Linkedin

Twitter