Duckpin Lane Dimensions and Layout Standards

- Duckpin Lane Dimensions and Layout Standards

- Introduction: What Defines a Duckpin Bowling Lane?

- Official Lane Dimensions: Foul Line, Length and Width

- Pin and Ball Specifications: Key Differences for Duckpin Bowling Lanes

- Approach, Foul Line, and Backstop: Practical Layout Considerations

- Pinsetter Options: Why Equipment Choice Matters for Duckpin Bowling Lanes

- Surface Materials and Oiling: Protecting Playability on Duckpin Bowling Lanes

- Accessibility, Safety and Local Codes: Compliance for Duckpin Bowling Lanes

- Space Planning: How Much Room Does a Duckpin Bowling Lane Need?

- Installation and Construction: Best Practices for Building Duckpin Bowling Lanes

- Maintenance and Operational Standards for Duckpin Bowling Lanes

- Comparison: Duckpin vs. Standard Ten‑Pin Lane Dimensions and Equipment

- Design Tips for Operators: Maximizing ROI on Duckpin Bowling Lanes

- Why Choose String Pinsetters for Duckpin Bowling Lanes?

- Flying Bowling: Partnering to Design and Build Duckpin Bowling Lanes

- FAQ — Common Questions About Duckpin Bowling Lanes

- Q: Are duckpin lane dimensions the same as ten‑pin lanes?

- Q: What pinsetter is best for a duckpin bowling lane?

- Q: Do duckpin lanes require different oil patterns?

- Q: How much space do I need to build a duckpin alley?

- Q: Can I convert existing ten‑pin lanes into duckpin lanes?

- Contact and Next Steps

- Sources

Duckpin Lane Dimensions and Layout Standards

Introduction: What Defines a Duckpin Bowling Lane?

A duckpin bowling lane is a specialized playing surface used for duckpin bowling, a popular variation of traditional ten‑pin bowling that uses smaller, squatter pins and smaller balls. While many physical lane dimensions follow the same baseline standards as ten‑pin bowling, several layout and equipment differences—pin size, ball size, pinsetter type, and scoring hardware—are critical for building and operating a regulation duckpin bowling alley. This guide answers the practical questions owners, architects, and operators ask when planning or modernizing a duckpin bowling lane and provides trusted guidance for compliance, design, and equipment procurement.

Official Lane Dimensions: Foul Line, Length and Width

The core playing surface dimensions for a duckpin bowling lane are generally consistent with ten‑pin standards: the distance from foul line to headpin is 60 feet (18.29 m), and the usable lane width is 41.5 inches (1.054 m). The approach area (where a bowler delivers the ball) is typically at least 15 feet (4.57 m) deep, matching common ten‑pin practice. These baseline dimensions are important when designing a facility because they determine space planning, approach layout, and structural depth.

Pin and Ball Specifications: Key Differences for Duckpin Bowling Lanes

Although the lane plate (length and width) is usually the same, the physical game elements differ significantly for a duckpin bowling lane. Duckpin pins are shorter and squatter than ten‑pin pins, and duckpin balls are much smaller and lighter, which affects pin action, oiling patterns, and pinsetter requirements. Expect lower pin heights and smaller pin diameters than ten‑pin; duckpin balls are handheld without finger holes and typically measure about 4.75–5.25 inches in diameter and weigh under 4 pounds. These differences influence how you select pinsetters (traditional free‑fall vs. modern string pinsetter), ball returns, and scoring systems that are adapted for duckpin rules.

Approach, Foul Line, and Backstop: Practical Layout Considerations

For a functional duckpin bowling lane, maintain a minimum approach depth of 15 feet to allow for comfortable delivery mechanics. Mark the foul line clearly and ensure the surface transitions smoothly from approach to lane surface. Behind the pins, provide adequate pin deck and pit area clearance for pinsetters and maintenance access. The backstop and pit depth should meet the manufacturer’s specification for the selected pinsetter—string pinsetters and specialized duckpin pinspotters often have different footprint requirements than standard ten‑pin machinery. Planning these clearances early prevents costly retrofits.

Pinsetter Options: Why Equipment Choice Matters for Duckpin Bowling Lanes

Equipment choice is one of the most consequential decisions for a duckpin bowling lane. Traditional free‑fall pinsetters used for ten‑pin are not always optimized for duckpin pins; many modern duckpin alleys use specialized pinspotters or string pinsetters tailored for smaller pins. String pinsetter systems reduce mechanical complexity, lower maintenance, and improve safety—advantages that are particularly attractive for smaller footprint duckpin centers or multi‑use entertainment venues. If your business model emphasizes lower operating costs and ease of installation, choosing a reputable string pinsetter system is often the right direction.

Surface Materials and Oiling: Protecting Playability on Duckpin Bowling Lanes

Lane surface composition—hardwood (maple/leno) or synthetic overlay—affects ball roll, durability, and maintenance frequency. Because duckpin balls are smaller and lighter, oil patterns and application methods must be adjusted: oils are often lighter and applied with patterns that encourage increased pin carry for small ball profiles. Whether you choose a wood or synthetic lane surface, work with lane conditioner manufacturers and equipment providers to establish oil pattern guidelines optimized for duckpin bowling lane playability and longevity.

Accessibility, Safety and Local Codes: Compliance for Duckpin Bowling Lanes

Local building codes, accessibility standards (such as ADA in the United States), and fire and egress requirements must inform your duckpin bowling lane layout. Ensure accessible lanes for players with limited mobility, provide clear sightlines, and plan for emergency exits and HVAC/ventilation. Mechanical rooms for pinsetters and ball return systems require ventilation and service access; follow manufacturer clearance specifications to comply with safety and warranty conditions. Consulting a local architect familiar with recreation facilities will minimize compliance risk.

Space Planning: How Much Room Does a Duckpin Bowling Lane Need?

When budgeting space, remember that a duckpin bowling lane requires more than just the playing lane. Typical space breakdown includes approach (≥15 ft), lane (60 ft), pin deck and pit clearance, seating and equipment (ball return, seating for players), and behind‑the‑lanes service areas. For a single lane, allocate a minimum depth of roughly 80–90 feet to include approach and pinsetter rooms; a full house of lanes requires planning for circulation, front‑of‑house entertainment areas, and mechanical rooms. Building codes and your chosen pinsetter footprint directly influence these numbers.

Installation and Construction: Best Practices for Building Duckpin Bowling Lanes

Construction steps for a duckpin bowling lane mirror those for standard lanes but with a few key considerations: ensure the subfloor and foundation are level and compatible with your chosen lane surface; install proper drainage and ventilation in pinsetter rooms; and coordinate electrical and control wiring for scoring systems and pinsetters early in the build. When integrating modern systems—automated scoring, string pinsetters, LED lane lighting—work with experienced bowling equipment manufacturers and installers to reduce on‑site rework. Proper pre‑planning saves time and improves the long‑term reliability of the duckpin bowling lane.

Maintenance and Operational Standards for Duckpin Bowling Lanes

Routine maintenance extends the life and play quality of a duckpin bowling lane. Regular tasks include lane surface cleaning and oiling, inspection of pinsetters (string or mechanical), lubrication schedules, and ball return system checks. Because duckpin balls are small and can introduce different wear patterns, monitor the lane surface and oil absorption, and adjust maintenance cycles accordingly. Implement a documented maintenance plan and train in‑house staff or contract a certified service provider to maintain compliance with warranty conditions and safety standards.

Comparison: Duckpin vs. Standard Ten‑Pin Lane Dimensions and Equipment

Below is a concise comparison table highlighting the typical dimensional similarities and key equipment differences between duckpin and ten‑pin lanes. These values reflect widely accepted industry norms and manufacturer recommendations.

| Item | Duckpin Bowling Lane | Ten‑Pin Bowling Lane (Standard) |

|---|---|---|

| Foul line to headpin | 60 ft (18.29 m) | 60 ft (18.29 m) |

| Lane width | 41.5 in (1.054 m) | 41.5 in (1.054 m) |

| Approach depth | ≥15 ft (4.57 m) | ≥15 ft (4.57 m) |

| Pin size | Smaller, squatter pins (duckpin) | Standard taller ten‑pin (approx. 15 in height) |

| Ball size/weight | Small, handheld balls ~4.75–5.25 in diameter; typically ≤4 lbs | Up to 8.5 in diameter; up to 16 lbs |

| Common pinsetter | Specialized duckpin pinspotters or string pinsetters | Free‑fall mechanical pinsetters (traditional) |

Sources for these comparative norms are included at the end of this article.

Design Tips for Operators: Maximizing ROI on Duckpin Bowling Lanes

When building or refurbishing duckpin lanes, consider the following practical tips: select equipment (string pinsetters, ball returns, scoring systems) optimized for duckpin to reduce long‑term maintenance; design flexible seating and entertainment areas to support mixed‑use operations (arcade, bar, party rooms); and plan lighting and signage to highlight lanes without causing glare. Investing in modern, low‑maintenance machinery and a compelling guest experience improves utilization, allowing operators to recover capital costs faster.

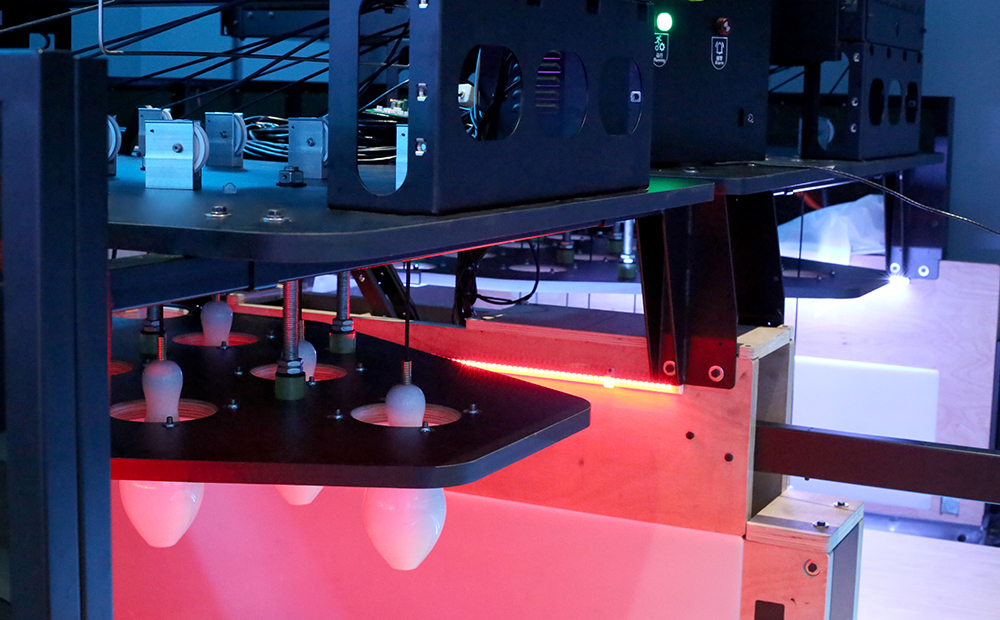

Why Choose String Pinsetters for Duckpin Bowling Lanes?

String pinsetters are increasingly popular in duckpin centers for several reasons: they require fewer moving parts, lower maintenance time and cost, reduce the size of the pinsetter room, and are easier to retrofit into existing spaces. For operators who want reliable play with lower operational overhead, string pinsetter systems often deliver a compelling lifecycle cost advantage. When evaluating systems, consider manufacturer support, parts availability, and remote technical assistance capabilities.

Flying Bowling: Partnering to Design and Build Duckpin Bowling Lanes

Since 2005, Flying Bowling has been researching and developing the latest and most advanced bowling equipment. We provide everything you need for your bowling alley, from equipment to design and construction. As a leading bowling equipment manufacturer and solutions provider in the domestic industry, we sell over 2,000 lanes a year worldwide, breaking the monopoly on traditional pinsetter equipment, enriching the international market, and offering our customers a wider range of options.

Through Flying Bowling's European Division, we maintain a sales office, permanent showroom, and 24/7 technical support to ensure customized solutions with the highest standards of quality and efficiency. Flying Bowling's European branch specializes in providing localized services to customers in Europe. Our bowling equipment has been certified by major global organizations, including CE and RoHS. We operate a 10,000‑square‑meter workshop where we manufacture bowling equipment, including bowling string pinsetters, bowling ball return machine systems, bowling scoring systems, and other bowling equipment. We build and modernize standard and duckpin bowling alleys, offering turnkey solutions for new builds and renovations.

Flying Bowling's core offerings for duckpin bowling lane projects include:

- Customized lane design and construction

- String pinsetter systems engineered for duckpin pins

- Integrated ball return and scoring system packages

- Post‑installation technical support and spare parts through our European branch

These capabilities make Flying Bowling a strong partner when you want an efficient, modern duckpin bowling lane that reduces maintenance costs while delivering excellent player experience. Visit https://www.flybowling.com/ to view products, request drawings, or contact our sales and technical teams.

FAQ — Common Questions About Duckpin Bowling Lanes

Q: Are duckpin lane dimensions the same as ten‑pin lanes?

A: Yes. The essential lane dimensions—60 feet from foul line to headpin and 41.5 inches lane width—are generally the same for duckpin and ten‑pin lanes. Differences arise primarily in pin, ball, and pinsetter equipment.

Q: What pinsetter is best for a duckpin bowling lane?

A: Specialized duckpin pinspotters or modern string pinsetters are commonly used. String pinsetters offer lower maintenance, smaller footprints, and are often easier to integrate into entertainment and hospitality venues.

Q: Do duckpin lanes require different oil patterns?

A: Yes. Because duckpin balls are smaller and lighter, operators typically use lighter oil volumes and different pattern shapes to promote pin carry. Work with lane conditioner manufacturers to establish the right oiling schedule.

Q: How much space do I need to build a duckpin alley?

A: Plan at least 80–90 feet depth per lane to include approach, lane, pin deck, and mechanical room clearances. Full facilities require additional space for circulation, seating, and support areas.

Q: Can I convert existing ten‑pin lanes into duckpin lanes?

A: In many cases, yes. Conversion typically involves changing pins, balls, pinspotting equipment or retrofit of string pinsetters, and adjusting oiling and maintenance procedures. Engage a professional equipment supplier like Flying Bowling to assess feasibility and cost.

Contact and Next Steps

If you are planning a new duckpin bowling lane, renovating existing lanes, or comparing pinsetter options, Flying Bowling offers end‑to‑end solutions: design, manufacturing, installation, and 24/7 technical support through our European division. Contact us to request a custom quote, technical drawings, or to visit our showroom: https://www.flybowling.com/. Our sales and technical teams can help you select the right equipment—bowling alley equipment, string pinsetter, duckpin bowling, and standard bowling solutions—tailored to your project goals and budget.

Sources

- United States Bowling Congress (USBC) — Official equipment and lane specifications and guidelines

- Wikipedia — Duckpin bowling article (overview of equipment and historic dimensions)

- Industry manufacturer specifications and product datasheets for string pinsetters and lane surfaces

Buying Quality Bowling Equipment

Products

Can I choose the color and brand logo of the equipment?

Personalized customization is supported, including lane color, LOGO, theme lighting system, etc.

Customer care

Do I get a discount if my bowling lanes are shorter than standard length?

Shorter lanes require additional labor to cut and splice materials, which offsets any potential material savings. As a result, pricing remains the same regardless of lane length.

Technology

Is there any charge for remote technical guidance?

Free lifetime remote video diagnostic service to quickly resolve software/settings issues

Company

What are the advantages of your brand compared with other international brands?

Compared with other international brands, our equipment has significant price advantages and lower maintenance costs. We provide customers with more cost-effective options by optimizing the design and manufacturing process while ensuring high quality and compliance with USBC international standards.

Service

Do you provide regular maintenance services?

You can sign an annual maintenance agreement, which includes quarterly inspections, lubrication maintenance, system upgrades and other services.

Flying Smart Duckpin Bowling

The innovative design of Flying Smart Duckpin Bowling (FSDB) makes it perfect for places like bars, billiard halls, and game centers. It makes people want to come back more often and spend more money. FSDB is fun and competitive, so it will become a new focus for social activities.

Flying Classic Standard Bowling

Flying Classic Standard Bowling (FCSB) employs the World Standard Competition Scoring System to deliver a more professional bowling experience, enabling bowlers to enjoy a professional-standard match at their convenience.

Flying Ultra Standard Bowling

Flying Ultra Standard Bowling (FUSB) Upgraded Version

The string pinsetter uses the latest technology. It offers a more enjoyable bowling experience thanks to its innovative designs and modern technology.

Ready to Build Your Bowling Center?

Share your details, and we’ll provide tailored solutions and expert guidance to help you take your bowling center to the next level.

Facebook

YouTube

Linkedin

Twitter